The Only Guide to Motorcycle Parts New Zealand Specialists

Table of ContentsThe 30-Second Trick For Motorcycle Parts New Zealand SpecialistsFacts About Motorcycle Parts New Zealand Specialists RevealedGetting My Motorcycle Parts New Zealand Specialists To WorkThe Single Strategy To Use For Motorcycle Parts New Zealand SpecialistsThe Facts About Motorcycle Parts New Zealand Specialists UncoveredSee This Report about Motorcycle Parts New Zealand SpecialistsThe Basic Principles Of Motorcycle Parts New Zealand Specialists Everything about Motorcycle Parts New Zealand Specialists

So, reach out to among our experts today.CNC machining modern technology is rapidly ending up being the centerpiece of numerous different production processes around the world as a direct result of its lots of advantages over various other methods. Additionally, the industries that produce motorcycles have hopped on board with this fad. One of the most ingenious firms are now establishing their engine parts and wheels making use of machining methods initially developed for motorcycle parts.

You might be questioning why we make use of. Now that we have your focus let us explain the rationale behind this modern growth in the bike production market.

The Only Guide to Motorcycle Parts New Zealand Specialists

In enhancement, you have full control over the appearance of the elements, even down to the min information. Occasionally, motorcyclists may choose to spruce up their adventure by mounting aftermarket parts or changing the bike's transformation.

Examine This Report about Motorcycle Parts New Zealand Specialists

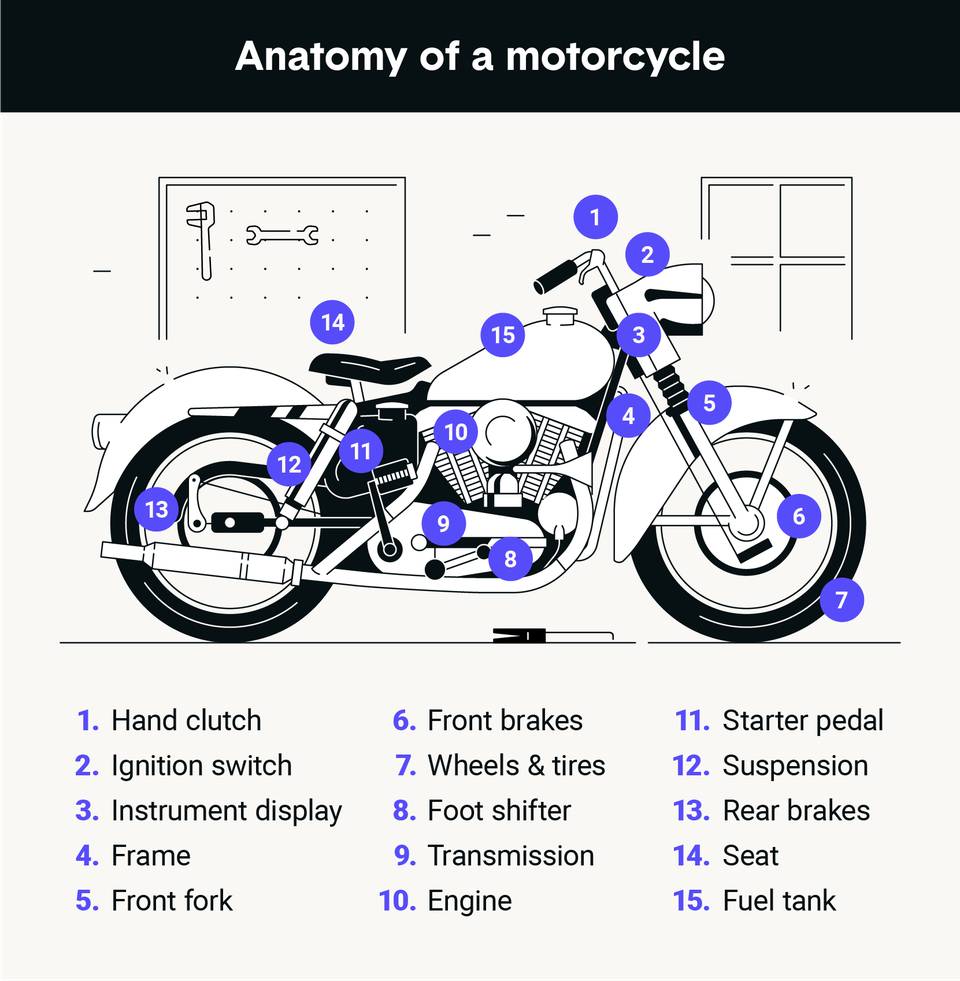

CNC machining might be used to make nearly all of a motorcycle's metal and plastic elements. To continue, we'll discuss several machined components for motorbikes.

Milling procedures are utilized to obtain the preferred level of wheel modification. Another facet of the motorbike that may be individualized is the tires.

Motorcycle Parts New Zealand Specialists Fundamentals Explained

When it involves an automobile (or a motorcycle), the most important element is the engine. Numerous people point to it as the "heart" of the automobile. On the various other hand, the camshaft, the cylinder head, and the pistons have a tendency to be elaborate and require layouts with a high level of accuracy.

Usage just high-quality products, however, since these lights are crucial for the security of motorcyclists and other motorists or individuals on the road, especially at evening. Motorcycle headlights have three main components: the light bulb, or light source, the lens, and the housing.

Milling processes with a remarkable surface would result in the lenses having a reflective quality that resembles that of a mirror. The cover, on the other hand, is not made up of breakable materials; rather, it is constructed out of challenging polymers that can be machined right into more elaborate patterns.

Some Of Motorcycle Parts New Zealand Specialists

They commonly have intricate geometries with a wide range of min details. Bike suppliers frequently cast these components, however just for the manufacturing of bespoke components. Nonetheless, CNC machining is the method of choice when producing unique pieces. Machining on five axes in today's world is the methods by which any design form might be recognized.

The success of the procedure is contingent on the mill cutters' capacity to determine subtle and complicated angles accurately. Choose Runsom for your personalized motorbike components! We have the capacity to check produce challenging and trendy parts making your bike incomparable. Most are crafted from light weight aluminum or steel alloys, each of which has its uses and advantages.

Below are a couple of examples of metals frequently made use of in bike component machining. Aluminum is the main material utilized by companies specializing in creating custom motorcycle parts to produce most of these parts - Motorcycle Parts New Zealand Specialists.

Zinc refers to another metal that is extremely light in weight and has terrific machining top qualities as a result of its high mechanical stamina. This material may be developed into almost any form this content and maintains its dimensions well. Also mission-critical parts that need a high level of accuracy may profit from their use.

Facts About Motorcycle Parts New Zealand Specialists Uncovered

Another steel that sees hefty usage in the manufacturing of CNC-customized elements is magnesium. It is among the lightest steels that are currently obtainable and has exceptional machinability features and toughness appropriate with its low weight. One of the disadvantages of magnesium is that its dirt may quickly catch fire.

Due to its superior machinability and weldability, stainless-steel is an alloy that is particularly fit for CNC procedures. They have wonderful deterioration resistance and a high aesthetic appeal. Their most common usage in generating various motorbike parts is fasteners, such as screws and bolts. Their low vulnerability to oxidation and corrosion makes them optimal for this usage.

Unknown Facts About Motorcycle Parts New Zealand Specialists

It appears that CNC turning and milling are the fundamental processes. However, alternate strategies exist, such as drilling. Let's examine a lot of these machining techniques comprehensive. The CNC transforming method is taken into consideration a subtractive production method. In addition, it needs keeping bars of product, most frequently plastic or metal, ready and after that turning a cutting device to get rid of areas of the material as the material is transformed.

These approaches are just as crucial and create parts with high accuracy and constant high quality. The procedures assist boost the overall top quality of the machined bike parts.

The Facts About Motorcycle Parts New Zealand Specialists Uncovered